X-Ray Inspection of a BGA

Ease or Dis-Ease of Miniaturization

In today’s world, miniaturization may be the holy grail of success in designing and building certain portable electronic equipment. A mobile phone is expected to substitute a laptop in functionality without growing a bit in size and weight. Many times design engineers can face an arduous task of increasing product features while reducing form factor and may need to use miniaturized BGA packages when available. For many types of ICs, such as FPGAs and high performance processors, BGA is the only package choice available these days.

However, a BGA cannot be hand-soldered and a manual pick and place machine may not be able to handle this chip. In most cases soldering BGAs require use of expensive assembly lines. Again with very high pin count BGAs, there is always that lingering doubt of whether all the pins are in proper contact with the PCB.

A bad contact or a missing ball is not easy to detect with laboratory optical equipment. An electrical test of the entire circuit may show good connectivity, but in long run a power-intensive system could fail.

How do we do a precise inspection of BGA solder quality? The answer is, using X-ray inspection.

X-ray Inspection Systems, Procedures and Results

|

| An X-ray inspection system |

An X-ray inspection system consists of an X-ray chamber in which an electronic board is placed and an X-ray camera that produces X-ray images of the inspected BGA IC on to an interfaced computer.

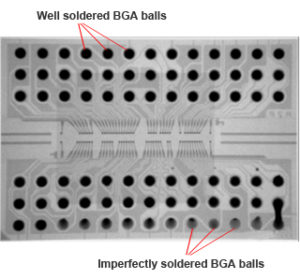

The X-ray camera moves in a grid pattern across the entire BGA under inspection inside the chamber. Such an inspection system meticulously unearths solder joint shorts, opens and voids of the inspected BGA by shade variance of balls. As observed in the image below of a typical BGA X-ray scan, the dark round balls indicate well connected and well soldered balls. The balls which looks very light indicate imperfectly soldered BGA balls.

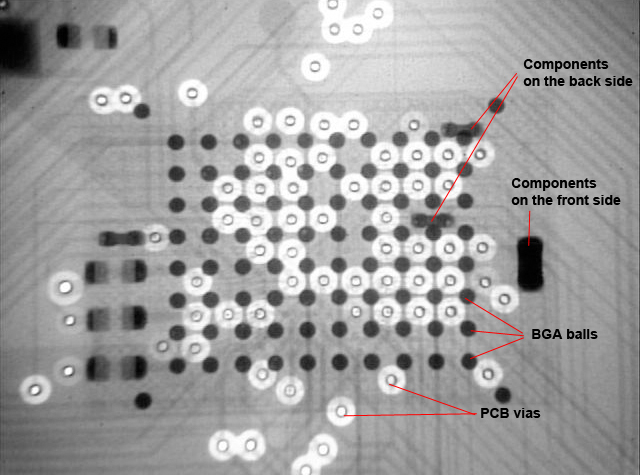

The image below of an 80-pin BGA shows the outcome of the X-ray scan done on a board manufactured by Ascenten. Here the clean round black patterns indicate proper soldering of the BGA balls.

A closer inspection of the above image infers–

- Seen are X-ray images of BGA balls, PCB vias and nearby components on the front and back side of the PCB.

- All BGA balls seem to be properly soldered as they all produce uniform dark circular images. Typically up to 5% lack in uniformity is tolerable.

- No shorting found among the BGA balls.

Since the BGA is a complex piece of technology and the density of pins is set to increase, it is always recommended that X-ray inspection is used to check the mounting of BGAs on PCBs. However, since the equipment needed for such inspection is expensive, most production houses pay as much attention as possible in the assembly line and then only hope best for the BGA solder quality.

Seizing business opportunity, some companies invest in separate X-ray test/inspection labs and entertain independent BGA testing assignments. These X-ray test/inspection labs maintain reasonable price points that make them viable for even small scale assembly lines. Some of these labs are also equipped with special BGA mounting equipment. These equipment operate on such high precision that an X-ray inspection after assembly may not even be required. Such mounting techniques are recommended for high pin density BGA.

References

- Wikipedia – http://en.wikipedia.org/wiki/Ball_grid_array

No Comments